As a conscientious manufacturer of sustainable packaging, we know we have a responsibility towards the environment. We rely on renewable energies in order to act in a sustainable way and protect our planet. Dürrbeck purchases electricity from TEAG Thüringer Energie AG, which gets its supply from existing hydropower plants in Scandinavia.

See our certificate of proof of origin from the power plants in Scandinavia by clicking the link below.

We continuously work to make our company as environmentally friendly as possible. That is why we strive to be as economical as possible when it comes to energy consumption, and to procure it only from sustainable resources. To do this, we frequently analyse our energy policy and adapt it to meet current framework conditions. This continuous improvement process is monitored once a year by an external audit pursuant to ISO 14001 and ISO 50001.

You can view and download our certificates here.

Our solutions:

Our innovative DKFol® -Eco and DKFol® - Eco-Coex formulas allow us to reduce:

Plus, it is a great way for you significantly conserve resources!

The use of reclaimed materials conserves resources and ideally creates a closed raw material cycle.

Here it is important to distinguish between industrial recycling and post-consumer materials.

PCR materials have a strong odour and yellow tint. These materials are well-suited for mailers and envelopes.

Recyclate from our own plastic film waste is regenerated in our in-house recycling process. Our manufacturing waste is sorted and the material that shows no signs of contamination can be processed thinly and is hardly distinguishable from virgin plastic, both visually and mechanically.

However, regenerates cannot be used for food packaging. We use these products only where possible hazardous residues (residues from adhesive tape, glue, dust, etc.) will not pose a threat (e.g. in the construction industry).

We commissioned ClimatePartner with comparing the CO2 emissions of new granulate/PCR granulate/internal recycling.

Results of the comparison (PDF): ClimatePartner Vergleich der CO₂-Emissionen verschiedener Kunststoffe auf Basis des „Greenhouse Gas Protocol Product Life Cycle Accounting and Reporting Standard“ (GHG Protocol).

Here we talk about three different biopolymer groups:

The main advantage of bio-based materials is the reduction in CO2. During the degradation process, microorganisms present in the environment convert the product into natural substances such as carbon dioxide, water and compost. This process is heavily dependent on environmental conditions (location, temperature) and can usually only be carried out at composting facilities.

However, it must be noted that bioplastics bring not only advantages but disadvantages as well. These can include:

The use of degradable biopolymers made from food waste is certainly a sensible solution for sustainable packaging; however, unfortunately the availability of these raw materials is limited.

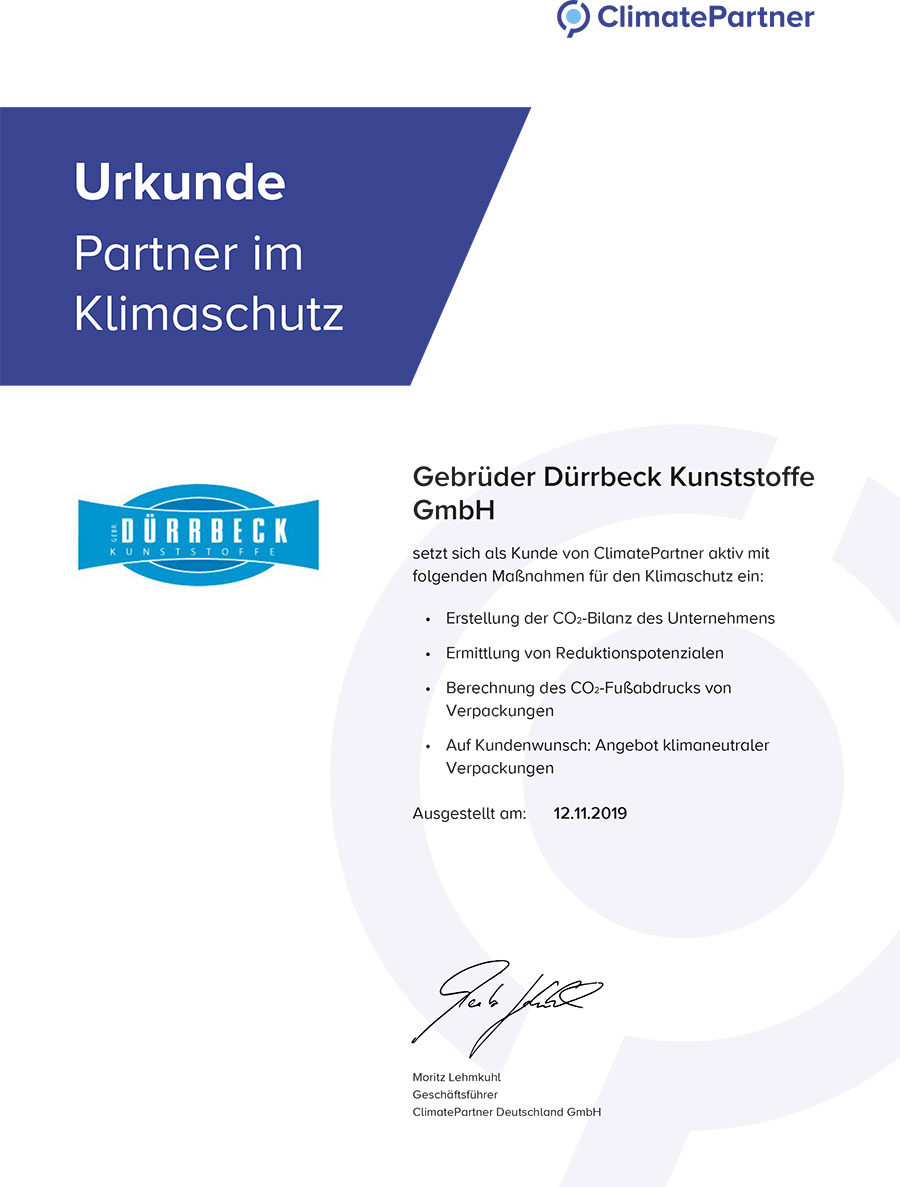

We had our product carbon footprint calculated for our production.

This determined the carbon emissions per kg of finished product.

Financial support for climate protection projects can neutralise the CO2 emissions that arise during the production of our plastic film.

This means there is no need to change the formula of your current plastic film, and its technical properties are retained.

If you are interested, we would be happy to put together a non-binding offer.

There are mineral fillers or additives that can be incorporated into plastics.

This saves raw material resources and improves our carbon footprint.

However, please note that these plastic films are not quite as transparent, but they do have a nice “natural, eco-friendly look”.

In the comparison, ClimatePartner assumed that:

Results of the comparison (PDF): ClimatePartner Berechnung der CO₂-Emissionen des Produktes PE-Versandtasche der Gebrüder Dürrbeck Kunststoffe GmbH auf Basis des „Greenhouse Gas Protocol Product Life Cycle Accounting and Reporting Standard“ (GHG Protocol)

Protecting the environment and saving energy are not only important duties of our company, but also a requirement for personal initiative and responsibility.

For this reason, the following principles form the basis of our drive for continuous improvement:

ClimatePartner Urkunde (PDF)